High Quality Titanium-Zirconium -Molybdenum Alloy

High quality Titanium-zirconium -molybdenum alloy: Physical Properties: MHC alloy performance and processing deformation

Basic Info

| Model NO. | alloy-01 |

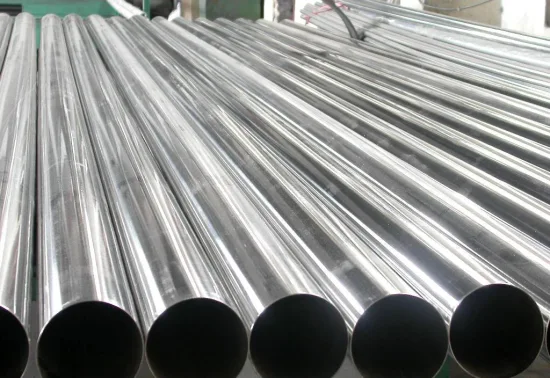

| Product Type | Rod |

| Material | FeMn |

| Carbon Content | High Carbon |

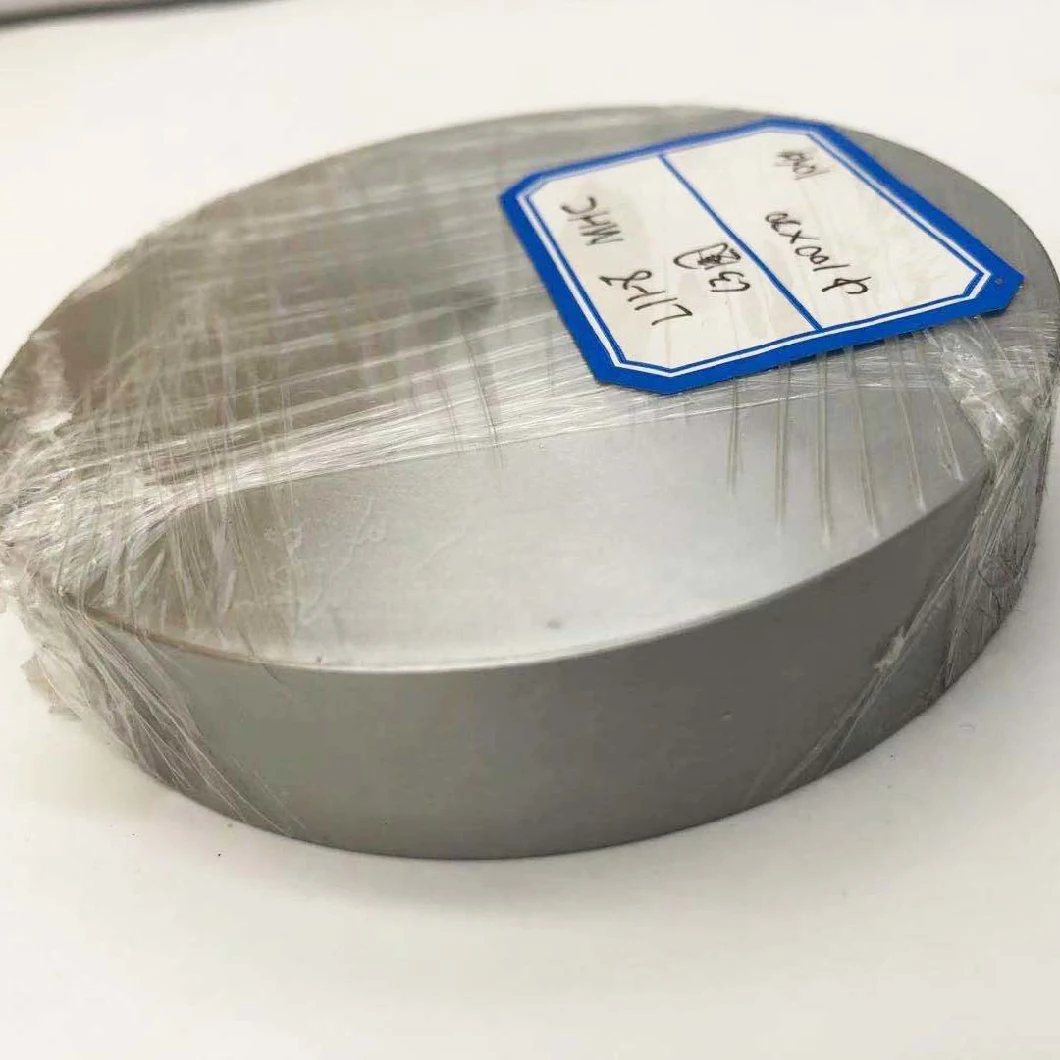

| PCD | 120mm |

| ET | 35mm |

| Hole | 5 |

| Transport Package | by Ply-Wood |

| Specification | 78*22 |

| Trademark | DC |

| Origin | Beijing, China |

| HS Code | 7313000000 |

| Production Capacity | 50PCS Each Month |

Product Description

High quality Titanium-zirconium -molybdenum alloy:

Physical Properties:

Hardness Vikers | HV | 280-320 |

Tensile Strength | Mpa | 830 |

Upper Yield Strength | Mpa | 786 |

Elongation after fracture | % | 26 |

Application | Mainly used for hot processing tools | |

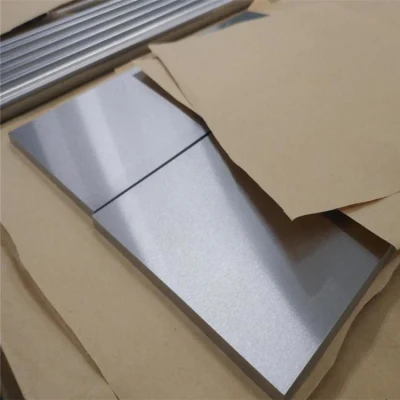

Available Size or Shape | Rod or other shape and size as per customers' requests | |

previous:

Titanium Ingot/Bar/Rod/Alloy

Send to us